Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

MIDI Controller Buttons

None

| Silicone Button Pad: | |

|---|---|

| Availability: | |

| Quantity: | |

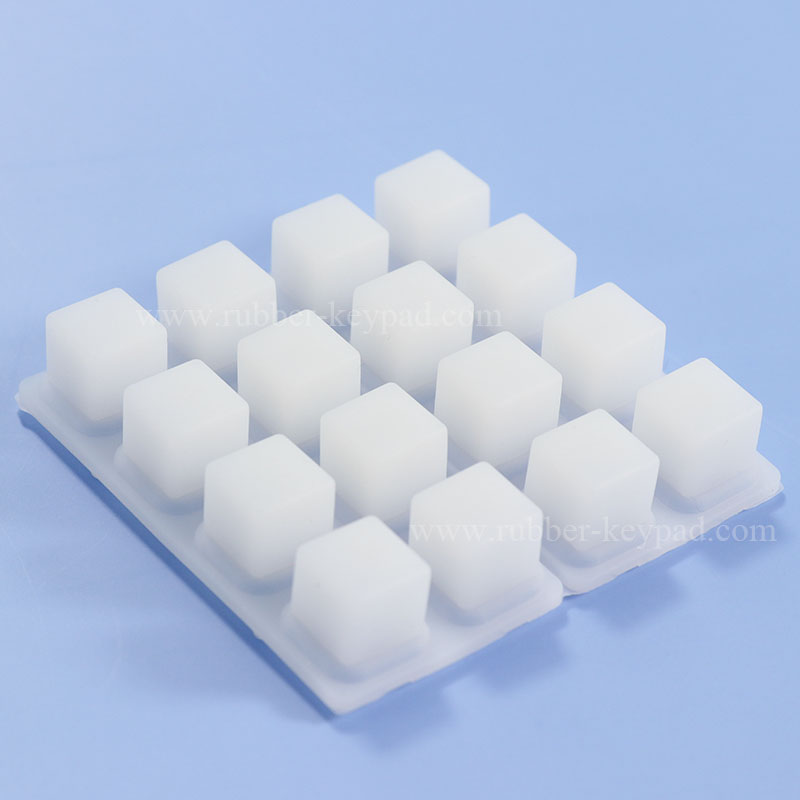

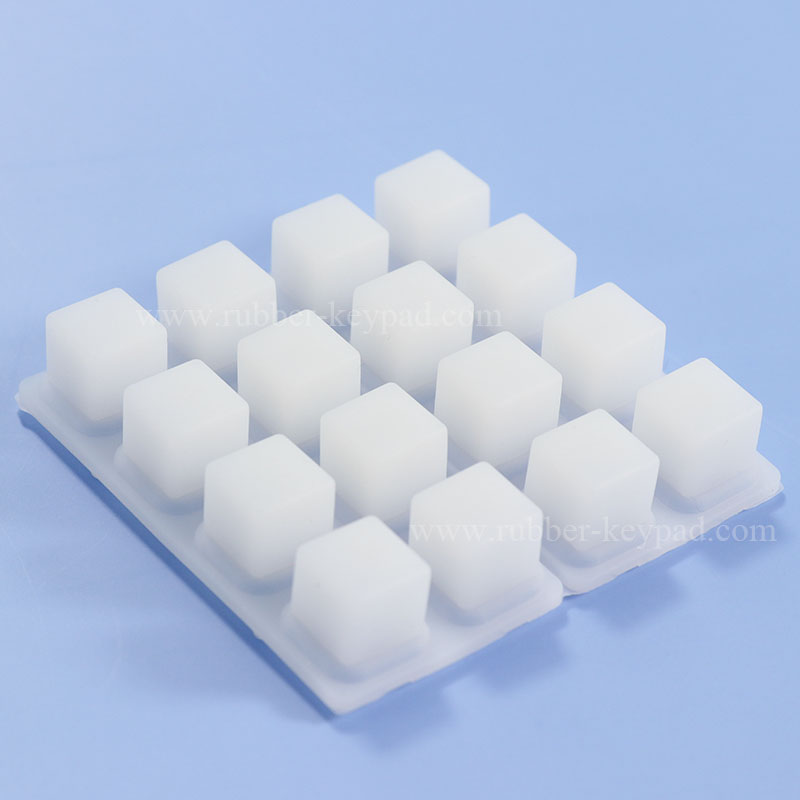

MIDI Controller buttons are silicone button pads used in MIDI (musical instrument digital interface) keyboard. MIDI buttons are made of translucent elastomer silicone to be with good resilience, using conductive carbon pills & graphite pads, or conductive ink as sensitive conduction. Common MIDI controllers buttons are transparent silicone button pad, and rubber contact strips for Yamaha MIDI keyboard or Casio keyboard.

Silicone Rubber Buttons for Yamaha PSR MIDI Keyboard

For more sizes details of stock standard MIDI controllers buttons, please refer to the 2D drawings below.

MIDI Controller Buttons Manufacturing Process

What are Good MIDI Controller Buttons?

MIDI Controller Buttons & Pads should be with light pressing force, but good tactile response, and sensitive conduction. That means silicone buttons should be with excellent acuation force and low- resistance carbon pills and ink. Silicone rubber material, and mold precision also affect performance of button pad. MIDI controller buttons can have longer working life and won't deform easily, if they are made of pure silicone with good resilience and tensile strength.

Actuation Force of MIDI Controller Buttons

Button actuation force relates to thickness of button webbing, and hardness of rubber.

Button webbing is the bridge connecting button keys with the button pad. It collapses when we press the button, but will rebund and return to its original status by itself when no force is put on it. Thick button webbing can generate heavy press force, while thinner one can decrease the actuation force.

In Yamaha PSR keyboard rubber buttons, we can see big differences about the acuation force between different rubber keys. The button webbing thickness of light rubber buttons is thiner than the thickness of heavy buttons.

Conductions of MIDI Buttons

MIDI Controller Buttons mainly be printed with conductive ink or combined with carbon pills as conduction part. Resistance of the conduction part has a great impact on sensitivity of rubber buttons. Using low-resistance ink and carbon pills can get a high-quality MIDI button pad. When the conductive ink doesn't fully cover the conduction area or the conductive ink is too thin, MIDI keyboard would perform insensitively and have bad tones.

MIDI Controller buttons are silicone button pads used in MIDI (musical instrument digital interface) keyboard. MIDI buttons are made of translucent elastomer silicone to be with good resilience, using conductive carbon pills & graphite pads, or conductive ink as sensitive conduction. Common MIDI controllers buttons are transparent silicone button pad, and rubber contact strips for Yamaha MIDI keyboard or Casio keyboard.

Silicone Rubber Buttons for Yamaha PSR MIDI Keyboard

For more sizes details of stock standard MIDI controllers buttons, please refer to the 2D drawings below.

MIDI Controller Buttons Manufacturing Process

What are Good MIDI Controller Buttons?

MIDI Controller Buttons & Pads should be with light pressing force, but good tactile response, and sensitive conduction. That means silicone buttons should be with excellent acuation force and low- resistance carbon pills and ink. Silicone rubber material, and mold precision also affect performance of button pad. MIDI controller buttons can have longer working life and won't deform easily, if they are made of pure silicone with good resilience and tensile strength.

Actuation Force of MIDI Controller Buttons

Button actuation force relates to thickness of button webbing, and hardness of rubber.

Button webbing is the bridge connecting button keys with the button pad. It collapses when we press the button, but will rebund and return to its original status by itself when no force is put on it. Thick button webbing can generate heavy press force, while thinner one can decrease the actuation force.

In Yamaha PSR keyboard rubber buttons, we can see big differences about the acuation force between different rubber keys. The button webbing thickness of light rubber buttons is thiner than the thickness of heavy buttons.

Conductions of MIDI Buttons

MIDI Controller Buttons mainly be printed with conductive ink or combined with carbon pills as conduction part. Resistance of the conduction part has a great impact on sensitivity of rubber buttons. Using low-resistance ink and carbon pills can get a high-quality MIDI button pad. When the conductive ink doesn't fully cover the conduction area or the conductive ink is too thin, MIDI keyboard would perform insensitively and have bad tones.

Silicone Rubber Keypad | Self Adhesive Gaskets | Rubber Sealing Gasket | Rubber Bellows | Rubber Button | Silicone Keyboard Cover | Membrane Keyboard | Membrane Switches | Remote Control Keyboard | POS Keyboard | Keypad Legends | Conductive Keypad | Keypad Cover | Keypad Feature | Liquid Silicone Rubber | Screen Printing Keyboard | Laser Keyboard | Conductive Metal Pills | Metal Dome | Conductive Button | Carbon Pills | Conductive Printing | Epoxy Coating | PU Coating | Matte Smooth | Color Coating | Plastic Key Cover | Metal Key Cover | Fluorescent keyboard | Molded Keypad | Backlight Keypad | Translucent Keyboard