Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 151 Author: rubber-keypad Publish Time: 2021-07-22 Origin: Site

Elastomer keypad and mechanical keyboard are widely used on the market.Each type uses a different method to open and close their respective switches. So, what’s the difference between elastomer keypads and mechanical keypads exactly?

What is Elastomer Keypad?

Elastomer Keypad also known as silicone elastomer keypad, silicone keypad, rubber keyboard.When you press a key on elastomer keypad, it presses down the part of key webbing and make it deform.When the whole keys are pressed, the conductive contacts on the key touches the PCB contacts below the keypad to complete the circuit, then the keypad conduction is done.If it is released, it will automatically pop out.This main principle is to use the conductive properties of conductive rubber to achieve conduction of keypad.

These switch contacts are very simple, which means they are cost effective and very durable.Unlike many other input devices , like mechanical keyboards, elastomer keypad have virtually unlimited useful life.

Elastomer keypads is the ability to make the entire keypad a single piece of silicone webbing, rather than having individual keys produced separately.

Elastomer keypad is made of silicone rubber material.It likes a cover to prevent dust and dirt from entering the device.It is also water-resistance.

What is Mechanical Keyboard?

Mechanical keyboard also called as gaming keyboard.Structurally, each key of the mechanical keyboard has a separate switch to control closure, also known as the "axis". According to the classification of microswitch, the mechanical keyboard can be divided into the traditional tea axis, green axis, white axis, black axis, red axis, Romer-G axis and optical axis.It is precisely because each button is composed of an independent micro-motion, so the button action is strong, thus achieving a special feeling suitable for game entertainment, so it is usually used as a relatively expensive high-end game peripherals.

Mechanical keyboards are different from other keyboards in that they have separate switches under the keys.These switches consist of several moving parts: a hard plastic "stem" containing two metal contacts and a spring underneath.When a key is pressed, the stem pushes the spring down so that the two metal contacts connect, recording your key press to the keyboard's circuitry, thus connecting it to your computer.

Difference between Elastomer Keypad vs Mechanical Keyboard material selection .

The key cap material of mechanical keyboard is generally plastic.But different requirements, different plastic material.

1.ABS(Acrylonitrile Butadiene Styrene plastic):

Odorless and non-toxic.

Temperature resistance -40℃-217℃.Thermal deformation temperature is 93-118℃.

Strong impact resistance, not deformation, and good insulation, not easily affected by humidity and frequency.

ABS material is the most common materials of mechanical keyboard keycap.The most important reason is that the process is mature and cheap.ABS key caps have various colors and can be made translucent to meet the needs of backlight.

2.POM (Polyoxymethylene):

Working temperature -40℃-100℃.

High density and high crystallization.Excellent wear resistance, high strength, insulation and wear resistance.

Strong oxidation and corrosion resistance.Resistant to organic solvents such as hydrocarbons, alcohols, aldehydes, ethers, gasoline, lubricating oil and weak base.

POM material key cap is less than ABS, so it is rarely seen in the original keyboard.It is a durable and simple material.Both durability and firmness of POM are better than ABS, oil resistance is also doubled.Handfeel between PBT and ABS.

3.PBT(Polybutylene terephthalate):

The most hard material.High strength, fatigue resistance, oil resistance, corrosion resistance, oxidation resistance, not easy to deform, not easy to change in high temperature.

Ageing resistance. It is the most stable key cap material.

PBT is relatively rare, but in the mechanical keyboard field is often mentioned.It should be the most reliable and the most excellent key cap material.

For the material of elastomer keypad, it is much simple.Material is silicone rubber, which is soft and flexible.

Elastomer keypads are manufactured from elastic, nontoxic silicone rubber compounds, which is processed by compression or injection molding. Elastomer keypad is economical and reliable.It is suitable for small, medium and large production runs.

Elastomer keypad natural color of raw silicone rubber material is translucent white. Raw materials are blended with color pigments to obtain the color required. Phosphorescent materials can be blended with the base rubber to create a “glow-in-the-dark” effect.

Elastomer keypad hardness is from 20 shore A-90 shore A.

Note: Silicone material is not resistant to oil and chemicals.So for some special application, we will suggest customer to use fluorosilicone rubber keypad.

Comparison Between Elastomer Keypad vs Mechanical Keyboard Structure.

Mechanical keypads also produce strong tactile feedback. As previously mentioned, one of the components used in their switches is a spring. The spring forces the individual keys to bounce back up. When you press and release a key, the key will bounce back up. This action creates tactile feedback, essentially notifying you that the keypad registered your command.

Elastomer keypad can be designed as conductive structure or non-conductive structure.

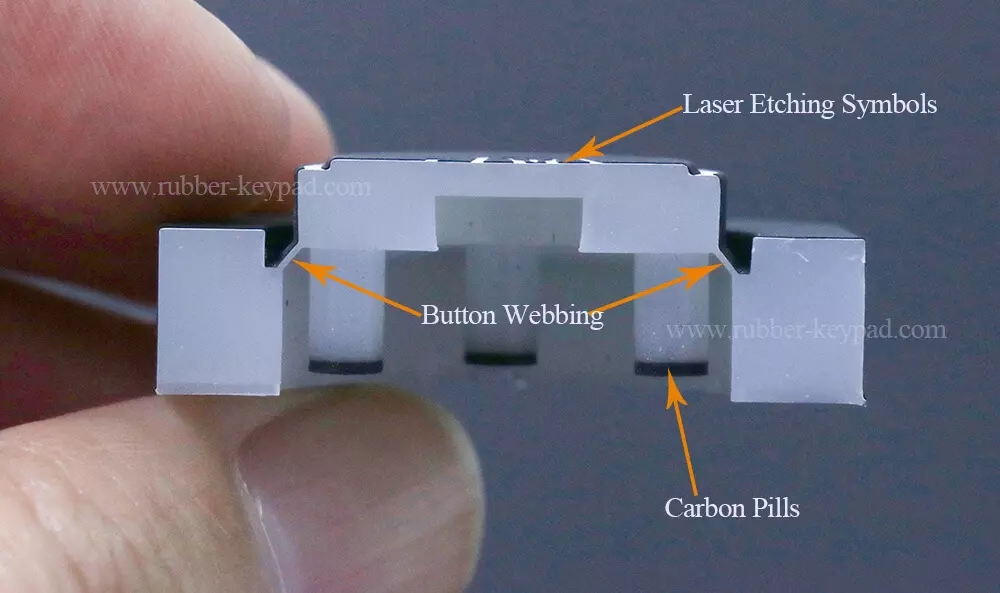

Conductive elastomer keypad contain a semi-conductive contact pill, which causes the keypad to be pressed down and generate electricity when it touches the PCB's contacts.

While for the non-conductive structure, the conduction contact is on the PCB, like tact switch, metal dome.

Know more about the elastomer keypad design guide.

Conductive Elastomer Keypad Structure vs Mechanical Keyboard Structure

Comparison Between Elastomer Keypad vs Mechanical Keyboard Surface Symbols Processing.

Laser etching processing

Both elastomer keypad and mechanical keyboard use laser etching processing to add symbols on the keyboard.But they are a little different.

At present, the most widely used in mechanical keyboard is the laser engraving process.Manufacturers add a certain special foaming in to key cap when production.

Then ablate(laser etch) the key cap surface by laser etching machine.The ablated part will show the opposite tone of the key cap itself.

Laser engraving is the most common process on non-backlit mechanical keyboards.

In contrast to mechanical keyboard, the laser etching processing of elastomer keypad will achieve backlit effect.

Elastomer keypad is made of transparent silicone first, then coat the different color ink to the clear keypad surface.Finally laser engrave the color ink to expose the needed symbols.So that the elastomer keypad can be backlit.

Elastomer keypad with laser etched symbols vs Mechanical keyboard with laser etched symbols

Silkscreen Printing processing

This is the most common way to process symbols on elastomer keypad, but few application on mechanical keyboards because of the short life time.

Elastomer keypad with silkscreen printed symbols vs Mechanical keyboard with printed symbols

Hollowing out printing processing

To hollow out the graphics and text, a mesh is used to transfer ink into the elastomer keypad or mechanical keyboard surface, expect that the graphics and text area is not permeable to the ink via a blocking stencil.Then moving the squeegee across the screen to fill the mesh interspace with ink.And a return movement will spread the ink into the elastomer keypad surface.

Hollowing out printing processing for both elastomer keypad and mechanical keyboard can achieve backlight effect.

Elastomer keypad with hollowing out printing vs Mechanical keyboard backlight

**The above three are relatively common processes to add symbols on elastomer keypad and mechanical keyboard.There are other processes, such as two-shot molding, transfer printing, dye sublimation.

Why Choose Elastomer Keypad or Mechanical Keyboard?

Elastomer keypad are popular for their superior strength and durability. Because silicone rubber is a soft material, it’s highly resistant to water. Elastomer silicone keypads can be used in humid environments, such as the outdoors.

This is because the silicone rubber webbing creates a protective shell over the underlying switches, thereby protecting them from moisture-related damage.Therefore when the elastomer silicone keypad is exposed to moisture, it won’t damage thanks to its construction.

Note: But silicone material is not resistant to oil and chemicals.So some for some special application, we will suggest customer to use fluorosilicone rubber keypad.

For mechanical keyboard, they typically cost less than other types of keypads, including elastomer silicone rubber keypads.So it is a choice if your budget is limited.

Silicone Rubber Keypad | Self Adhesive Gaskets | Rubber Sealing Gasket | Rubber Bellows | Rubber Button | Silicone Keyboard Cover | Membrane Keyboard | Membrane Switches | Remote Control Keyboard | POS Keyboard | Keypad Legends | Conductive Keypad | Keypad Cover | Keypad Feature | Liquid Silicone Rubber | Screen Printing Keyboard | Laser Keyboard | Conductive Metal Pills | Metal Dome | Conductive Button | Carbon Pills | Conductive Printing | Epoxy Coating | PU Coating | Matte Smooth | Color Coating | Plastic Key Cover | Metal Key Cover | Fluorescent keyboard | Molded Keypad | Backlight Keypad | Translucent Keyboard