Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 787 Author: Site Editor Publish Time: 2019-02-15 Origin: Site

Silicone rubber keyboard can be divided into conductive rubber keypad and non-conductive silicone keypad.

The conductive silicone button is the silicone button pad with conductive function to meet the electrical performance requirements of the device. There are two ways to achieve the conductive function of the silicone rubber buttons. One is to do conductive carbon pills during molding, and the other is to do conductive ink printing or slkscreen printing conductive painting after molding. Both processes have defects during production. Let's share the reasons for the poor conductivity of the silicone button and the improvement measures.

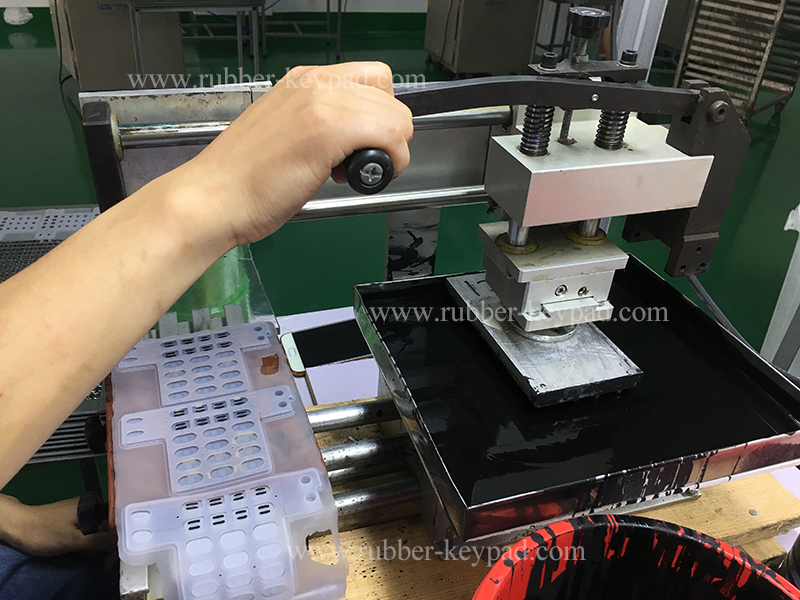

Conductive Carbon Pills Rubber Buttons Conductive Ink Printing Silicone Keypad

Silicone Rubber Keypad Manufacturing Process

Defects of carbon pills

1.The carbon pills fall off after compression molding

(1)Reason:The lower mold temperature is low, which causes the graphite pads of conductive silicone keyboard to fall off.

The conductive black carbon pills fall off when scrap slightly by hand, and there is no trace of conductive carbon pills on the conductive base of the rubber button pad.Furthermore,the bottom of the conductive rubber button pad is soft.

Solution:Increase the lower mold temperature.

(2)Reason:The rubber material is kept too long.

After the rubber material is mixed, it needs to be used up within 72H. If the storage time is too long, the vulcanizing agent of the rubber will volatilize and the fluidity of the rubber will be poor.

The conductive black carbon pills fall off when scrap slightly by hand, and there is no trace of conductive carbon pills on the conductive base of the rubber button pad. And incomplete filling of the silicone rubber buttons.

Solutions: Remix the silicone rubber material by adding appropriate amount of vulcanizing agent.

(3)Reason: Insufficient curing time.

The conductive black carbon pills fall off when scrap slightly by hand, and there is no trace of conductive carbon pills on the conductive base of the rubber button pad.

And incomplete filling of the silicone rubber buttons.The rubber buttons is soft and have air bubbles.

Solutions:Prolonged curing time.

(4)Reason:The carbon pills get dirty and damp because of improper storage, which causes poor adhesion of carbon pills and rubber button pads.

Solutions:Replace the clean black graphite pads or use it after drying.

2.The conductive graphite pads deformation (tilt)

(1)Reason: The position of the carbon pills deformation (tilt) is fixed or basically unchanged. Generally, the silicone button exhaust travel is too large or the conductive carbon pills are irregular, and carbon pill hole position of tooling is large, which will cause the carbon pill fall off.

Solutions: Reduce the molding exhaust travel and replace the carbon pills, or repair tooling.

(2) Reason: The position of carbon pills deformation (tilt) is not fixed or irregular. This situation is generally caused by too many times of exhaust during molding. In addition, too high temperature of the lower mold will cause such defects.

Solutions: Reduce the exhaust time and temperature.

3.Deviation position of conductive carbon pill

(1)The deviation position of conductive carbon pill is not fixed or irregular. Usually, it is caused by improper placement of conductive carbon pills or moving the carbon pills belt out of position when placing the material. Also because of the shallow position of carbon pills on tooling,which can not fix the conductive carbon pills.

(2)The deviation position of conductive carbon pill is fixed.This defect is mainly caused by large guide pins gap of the silicone button molding, or deformation of molding.

4.The conductive graphite pads rupture

The main reason is that when place the black carbon pills, it is too hard to to cause the carbon pills ruptured. The other reason is that the conductive carbon pills have burr.

5.The carbon pills overlap

The overlap of carbon pills is also called double carbon pills and short carbon pills. The carbon pills height of some keys is shorter than most keys.

The two conductive carbon pills were discharged in the same position because the carbon pills were not checked clearly when placing the material.

6.Silicone material on carbon pills

After the silicone button molding, the edge of the conductive carbon pill is wrapped by a layer of rubber material, which is caused by the large hole of the conductive carbon pill tooling or the small size of the conductive carbon pills.

Silicone Rubber Keypad | Self Adhesive Gaskets | Rubber Sealing Gasket | Rubber Bellows | Rubber Button | Silicone Keyboard Cover | Membrane Keyboard | Membrane Switches | Remote Control Keyboard | POS Keyboard | Keypad Legends | Conductive Keypad | Keypad Cover | Keypad Feature | Liquid Silicone Rubber | Screen Printing Keyboard | Laser Keyboard | Conductive Metal Pills | Metal Dome | Conductive Button | Carbon Pills | Conductive Printing | Epoxy Coating | PU Coating | Matte Smooth | Color Coating | Plastic Key Cover | Metal Key Cover | Fluorescent keyboard | Molded Keypad | Backlight Keypad | Translucent Keyboard