Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

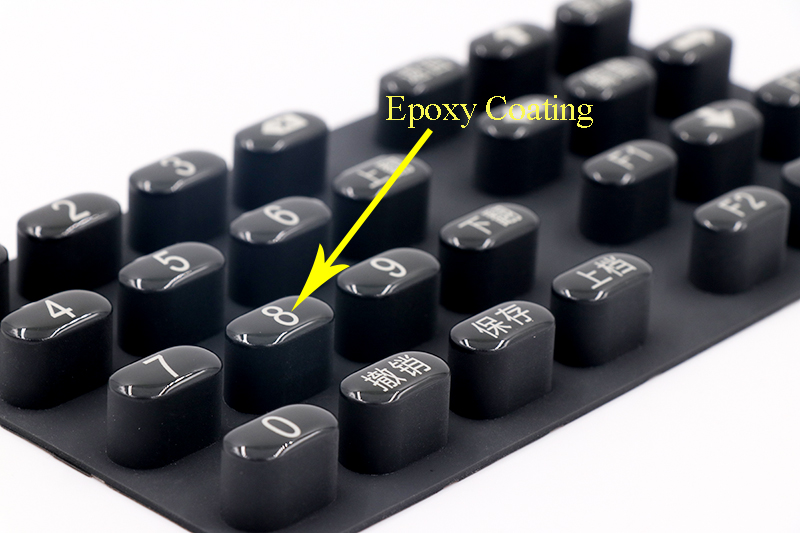

Epoxy Coating Keypad

Applying an epoxy crown to keytops is visually appealing as an economical processing.

An Epoxy Coating can be applied to conductive rubber keypads to give the keypad a hard plastic feel. This method is used as an alternative to custom keypads with plastic keytops.

Quickly Quotation Requirements

1. Offer 2D, 3D design (PDF, CAD, STEP, IGS, slprt. ) drawings, or samples

2. Include number of legend and silicone colors, Of need silicone light guide.

3. With or without carbon pills

4. Keypads surface demands: Laser Etched, Silkscreen, Spray Coating, UV Coating etc.

5. Quantities to be quoted

These are the primary elements for a quotation.

Other details such as travel, force, durometer and tactile response can be determined at the time of order.

Specialty features such as protective coatings, laser etching, light pipes, etc.

should be included.

Our Advantages:

1. Precision Own Mold-Making Technology (Since 1998)

2. Competitive Price: Origin Manufacturer.

1.) Mold-Making Plant

2.) Silicone Rubber Compression Plant

3.) Plastic Injection Plant

4.) Liquid Silicone Rubber Injecton Plant (LSR)

5.) Assembly Plant.

3. Five Experienced Designers and Engineers

4.Production and Test strictly according to ISO9001.

Test Equipment: 3D Projectors, Sealing Testor, Elasticity Measurement, Durometer etc.

5. Production Environment

6. Rapid Reaction Organization: Support Customer at short time

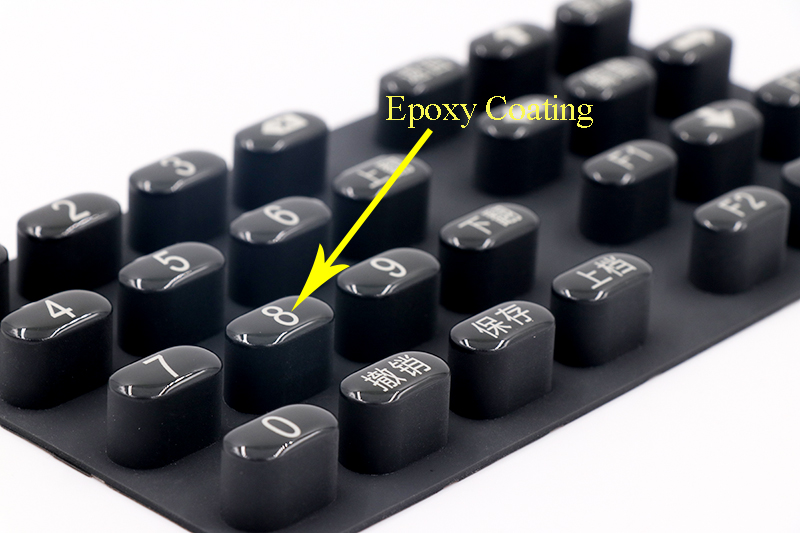

Epoxy Coating Keypad

Applying an epoxy crown to keytops is visually appealing as an economical processing.

An Epoxy Coating can be applied to conductive rubber keypads to give the keypad a hard plastic feel. This method is used as an alternative to custom keypads with plastic keytops.

Quickly Quotation Requirements

1. Offer 2D, 3D design (PDF, CAD, STEP, IGS, slprt. ) drawings, or samples

2. Include number of legend and silicone colors, Of need silicone light guide.

3. With or without carbon pills

4. Keypads surface demands: Laser Etched, Silkscreen, Spray Coating, UV Coating etc.

5. Quantities to be quoted

These are the primary elements for a quotation.

Other details such as travel, force, durometer and tactile response can be determined at the time of order.

Specialty features such as protective coatings, laser etching, light pipes, etc.

should be included.

Our Advantages:

1. Precision Own Mold-Making Technology (Since 1998)

2. Competitive Price: Origin Manufacturer.

1.) Mold-Making Plant

2.) Silicone Rubber Compression Plant

3.) Plastic Injection Plant

4.) Liquid Silicone Rubber Injecton Plant (LSR)

5.) Assembly Plant.

3. Five Experienced Designers and Engineers

4.Production and Test strictly according to ISO9001.

Test Equipment: 3D Projectors, Sealing Testor, Elasticity Measurement, Durometer etc.

5. Production Environment

6. Rapid Reaction Organization: Support Customer at short time

Silicone Rubber Keypad | Self Adhesive Gaskets | Rubber Sealing Gasket | Rubber Bellows | Rubber Button | Silicone Keyboard Cover | Membrane Keyboard | Membrane Switches | Remote Control Keyboard | POS Keyboard | Keypad Legends | Conductive Keypad | Keypad Cover | Keypad Feature | Liquid Silicone Rubber | Screen Printing Keyboard | Laser Keyboard | Conductive Metal Pills | Metal Dome | Conductive Button | Carbon Pills | Conductive Printing | Epoxy Coating | PU Coating | Matte Smooth | Color Coating | Plastic Key Cover | Metal Key Cover | Fluorescent keyboard | Molded Keypad | Backlight Keypad | Translucent Keyboard