Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

MS-2

Better

| Quantity: | |

|---|---|

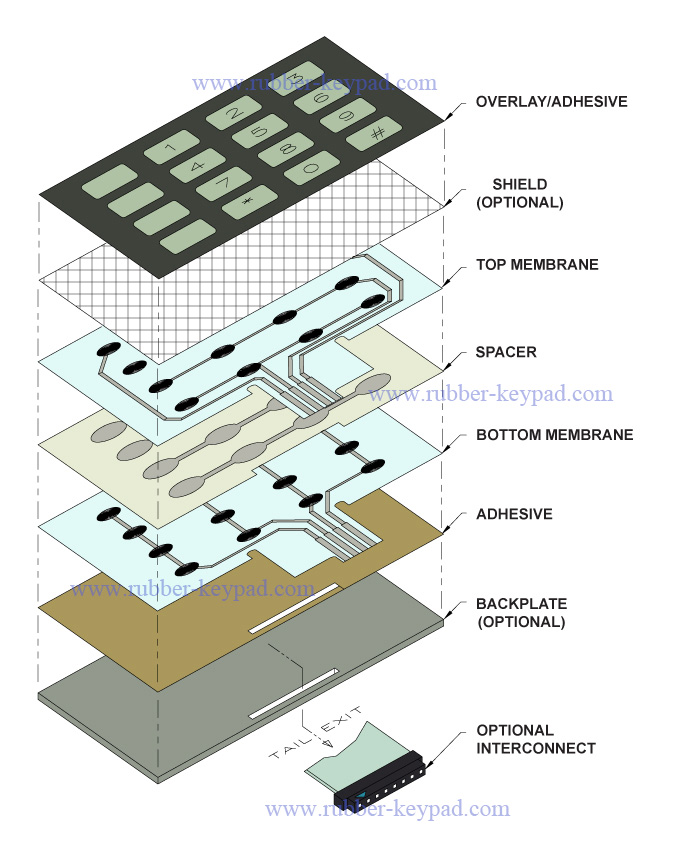

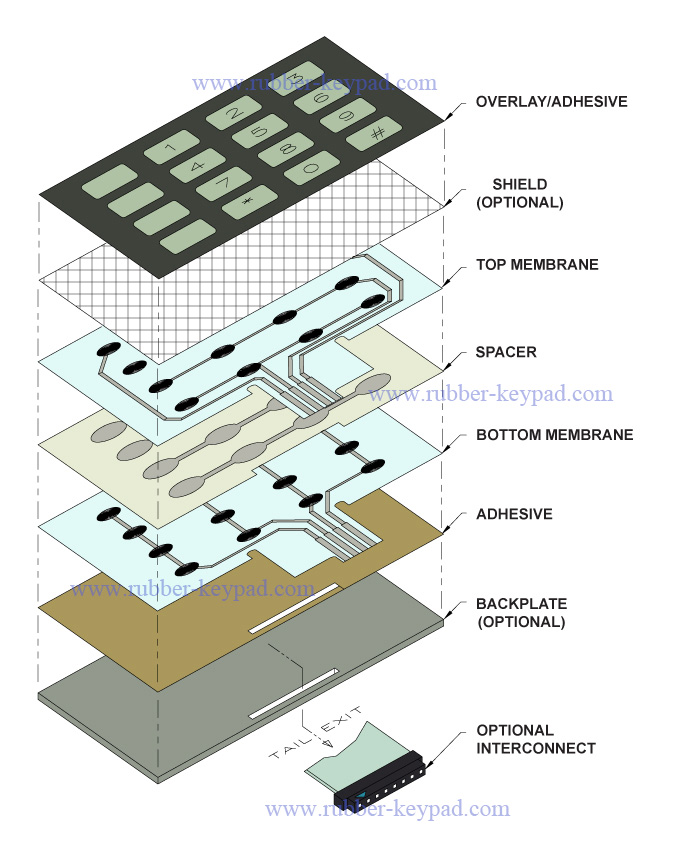

Silicone Rubber Keypad | Self Adhesive Gaskets | Rubber Sealing Gasket | Rubber Bellows | Rubber Button | Silicone Keyboard Cover | Membrane Keyboard | Membrane Switches | Remote Control Keyboard | POS Keyboard | Keypad Legends | Conductive Keypad | Keypad Cover | Keypad Feature | Liquid Silicone Rubber | Screen Printing Keyboard | Laser Keyboard | Conductive Metal Pills | Metal Dome | Conductive Button | Carbon Pills | Conductive Printing | Epoxy Coating | PU Coating | Matte Smooth | Color Coating | Plastic Key Cover | Metal Key Cover | Fluorescent keyboard | Molded Keypad | Backlight Keypad | Translucent Keyboard