Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

SKD-

Better

3926901000

| Quantity: | |

|---|---|

| Silicone Rubber Keypad Contacts | ||||

| | Carbon Pill | Conductive Ink Printing | Metal Domes | Metal Conductive Pill |

| Life Time | About 10 Millions | About 10 Millions | About 10 Millions | Above 10 Millions |

| Resistance | 10-100 Ohms | 50-350 Ohms | 1-100 Ohms | 1-100 Ohms |

| Diameter | 1.5-8mm | Available | Available | Available |

| Thickness | 0.2-0.6mm | 10-20 Microns | 0.05mm-0.1mm | 0.05mm-2mm |

| Advantage | Lower Resistance Stable Life Time | Any Shape is Available | Lower Resistance | Lower Resistance |

| DisAdvantage | Shape Limted | Resistance Limited | Bad Tactile Feel eithout Dust-free Functions | Low Production Efficiency, High Unit Price |

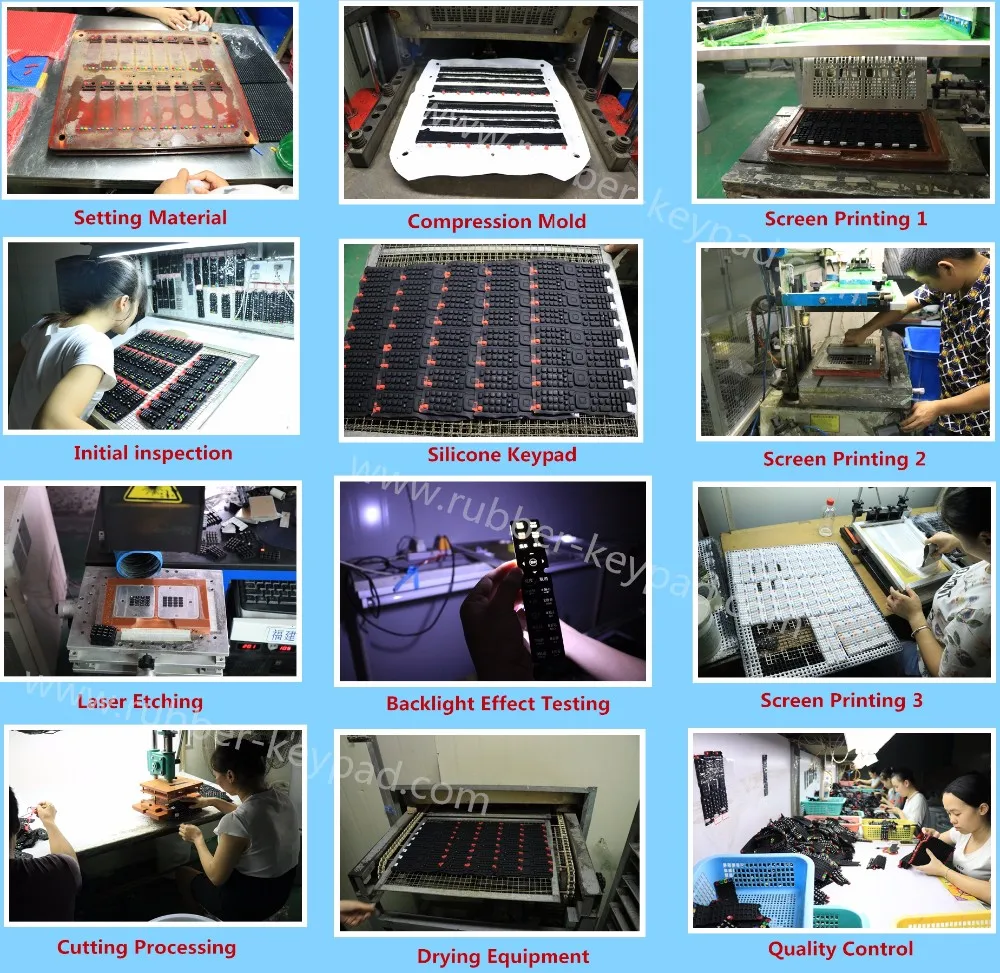

| Legends | Screen Printing Keypad |

| Laser Etched Keypad | |

| Molded Legends Keypad | |

| Protective Cover | Color-filled-in Keypad |

| PU Spraing Coating Keypad (Matte&Bright Surface) | |

| Matte Smooth Coating Keypad | |

| Epoxy Coating Keypad | |

| Plastic + Rubber Keypad (Plastic Key Cap & Cover) | |

| Metal + Rubber Keypad (Metal Key Cover) |

| Silicone Rubber Keypad Contacts | ||||

| | Carbon Pill | Conductive Ink Printing | Metal Domes | Metal Conductive Pill |

| Life Time | About 10 Millions | About 10 Millions | About 10 Millions | Above 10 Millions |

| Resistance | 10-100 Ohms | 50-350 Ohms | 1-100 Ohms | 1-100 Ohms |

| Diameter | 1.5-8mm | Available | Available | Available |

| Thickness | 0.2-0.6mm | 10-20 Microns | 0.05mm-0.1mm | 0.05mm-2mm |

| Advantage | Lower Resistance Stable Life Time | Any Shape is Available | Lower Resistance | Lower Resistance |

| DisAdvantage | Shape Limted | Resistance Limited | Bad Tactile Feel eithout Dust-free Functions | Low Production Efficiency, High Unit Price |

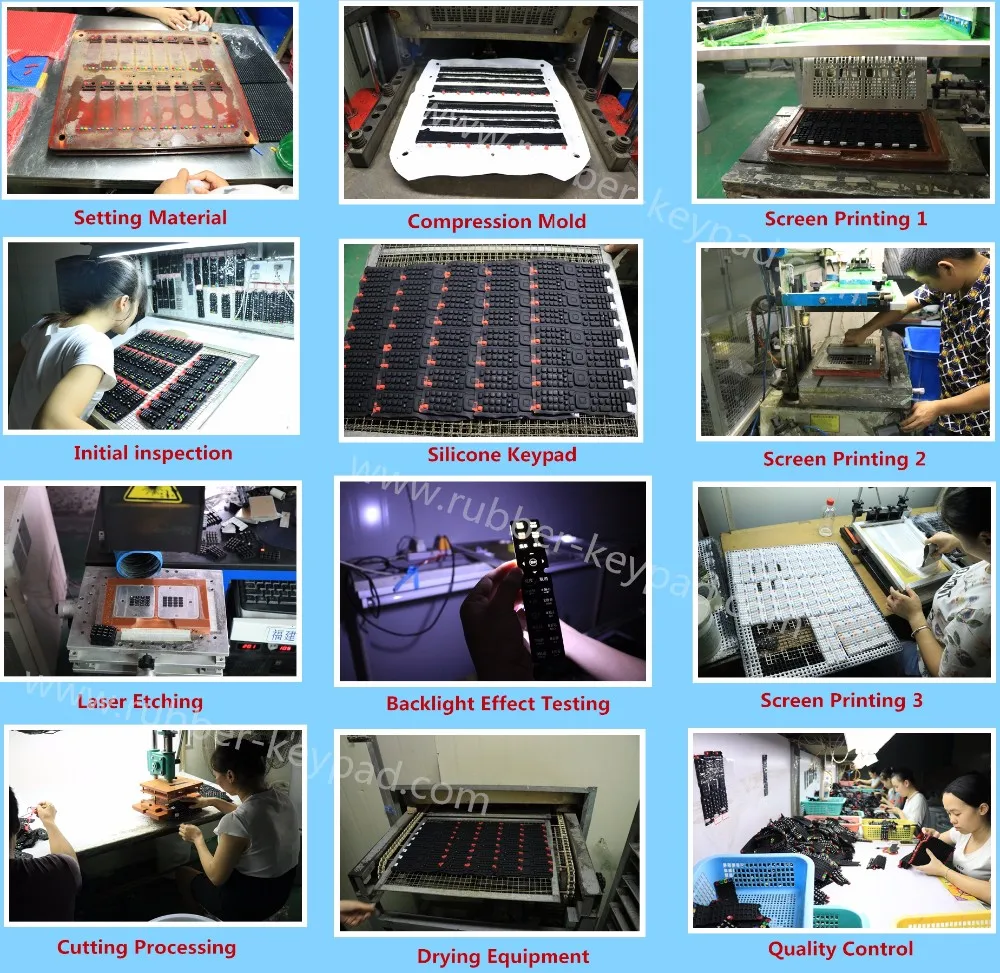

| Legends | Screen Printing Keypad |

| Laser Etched Keypad | |

| Molded Legends Keypad | |

| Protective Cover | Color-filled-in Keypad |

| PU Spraing Coating Keypad (Matte&Bright Surface) | |

| Matte Smooth Coating Keypad | |

| Epoxy Coating Keypad | |

| Plastic + Rubber Keypad (Plastic Key Cap & Cover) | |

| Metal + Rubber Keypad (Metal Key Cover) |

Silicone Rubber Keypad | Self Adhesive Gaskets | Rubber Sealing Gasket | Rubber Bellows | Rubber Button | Silicone Keyboard Cover | Membrane Keyboard | Membrane Switches | Remote Control Keyboard | POS Keyboard | Keypad Legends | Conductive Keypad | Keypad Cover | Keypad Feature | Liquid Silicone Rubber | Screen Printing Keyboard | Laser Keyboard | Conductive Metal Pills | Metal Dome | Conductive Button | Carbon Pills | Conductive Printing | Epoxy Coating | PU Coating | Matte Smooth | Color Coating | Plastic Key Cover | Metal Key Cover | Fluorescent keyboard | Molded Keypad | Backlight Keypad | Translucent Keyboard