Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

FK-1

Better

3926901000

| Quantity: | |

|---|---|

Characters or symbols on silicone keypad’s surface

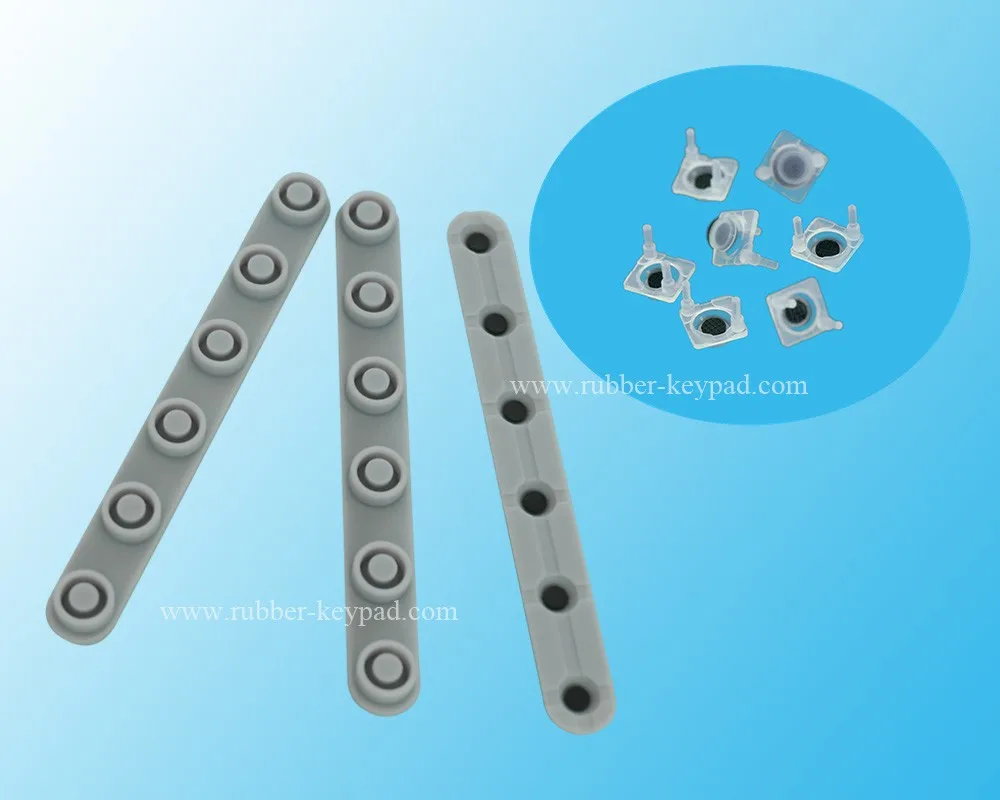

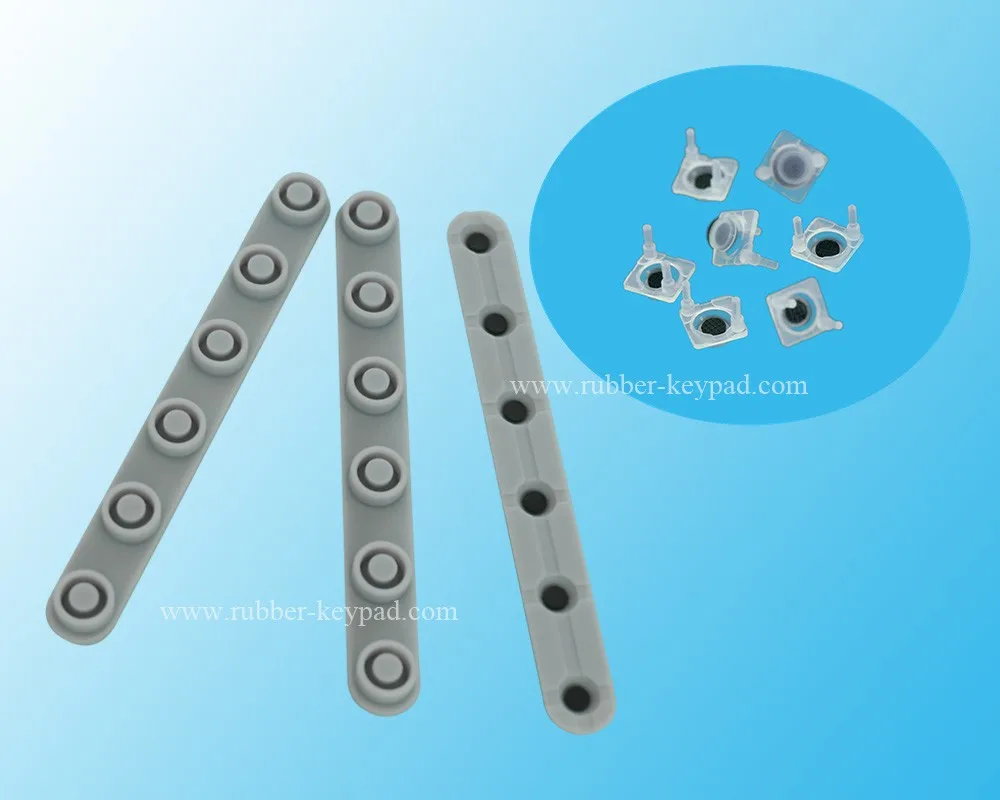

We also have single button ,3 button (key) and 5 button (key) button pad.

Make good use of silicone materials characteristics:

Translucent; Or Translucent Silicone + Color Toner

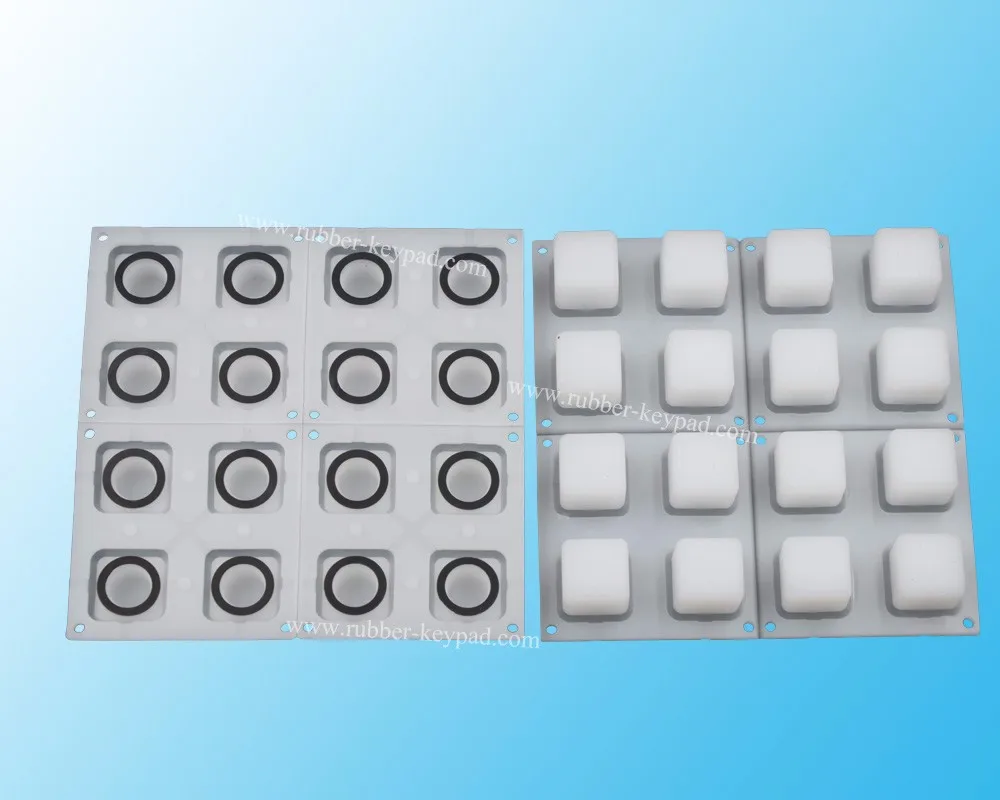

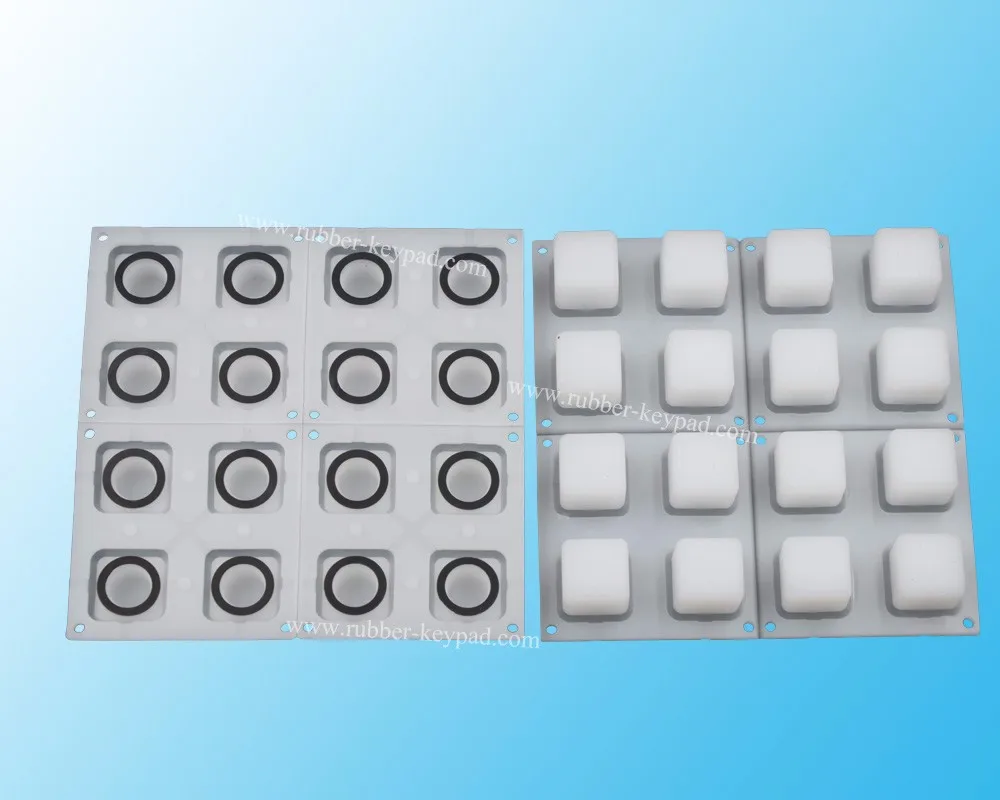

Produce dual or multiple buttons( keys) in one keypads by key-setting tooling.

when molded keypad production

Key top is coated (drop) by epoxy which have abrasion PU Coating is Polyurethane Coating, which is a kind of surface process

resistance function and can resist chemical or oil. for protecting silicone keypad’s character, symbols, or color spraying coating etc

Also improve keypad ornate-crystal beauty. Coated

color ( inner color) is the same to surface legend color.

Take full advantage of the benefits of plastic key cap with the Need laser cutting process to making desired character or symbols.

elastomeric and sealing feature of silicone rubber keypads First coated color ( inner color) is the same to the desired character or symbols color.

by glue or under-cut designs

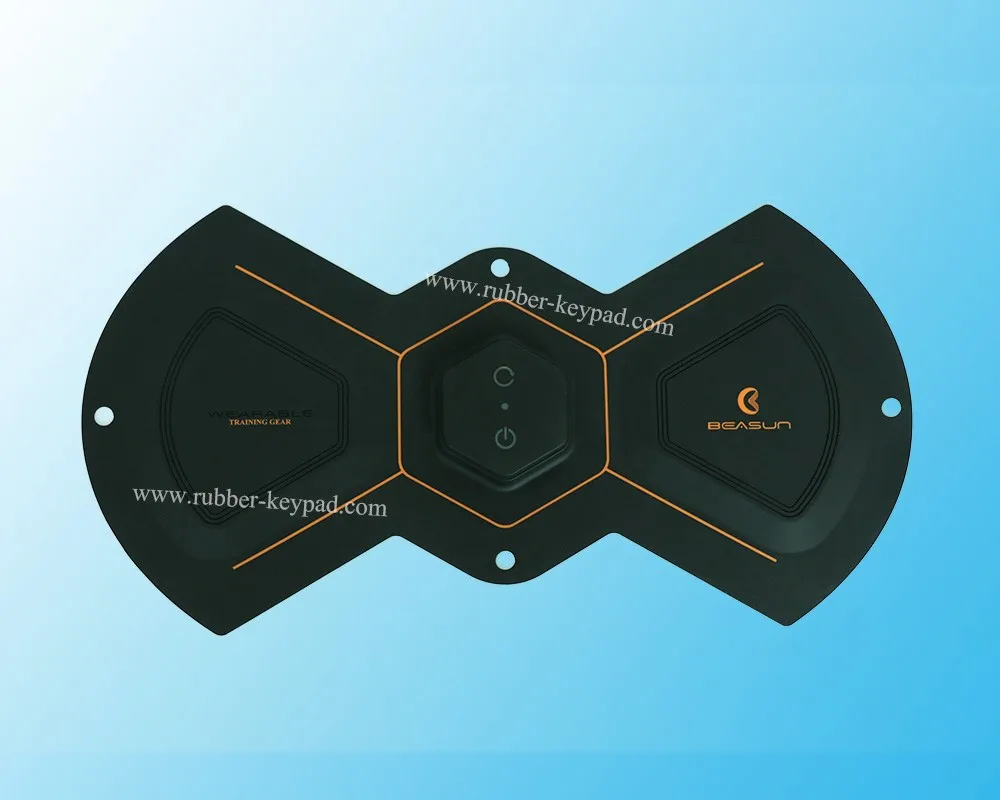

Common products in our daily life, TV sets, air-conditions etc

home appliance

Protect electronic product’s switch and improve sense of touch.

Made of stainless steel, a part of switch devices. Silicone Keypad with metal pill is known as silicone keypad over molded

Lower resistance and better conductivity. with copper pill, gold pill and so on.

A process for choosing conductivity ink instead of black Buttons + Silicone pad overmolded keypad is in aim to

carbon pills as non-conductive substrate’s conductive improve keypad touch feelings, also have aesthetic feeling

point or conductive circuit. conpared with Key-setting keypad.

Keypad Contact Types

| Silicone Rubber Keypad Contacts | ||||

| | Carbon Pill | Conductive Ink Printing | Metal Domes | Metal Conductive Pill |

| Life Time | About 10 Millions | About 10 Millions | About 10 Millions | Above 10 Millions |

| Resistance | 10-100 Ohms | 50-350 Ohms | 1-100 Ohms | 1-100 Ohms |

| Diameter | 1.5-8mm | Available | Available | Available |

| Thickness | 0.2-0.6mm | 10-20 Microns | 0.05mm-0.1mm | 0.05mm-2mm |

| Advantage | Lower Resistance Stable Life Time | Any Shape is Available | Lower Resistance | Lower Resistance |

| DisAdvantage | Shape Limted | Resistance Limited | Bad Tactile Feel eithout Dust-free Functions | Low Production Efficiency, High Unit Price |

Keypad Legend Types and Surface Protection

| Legends | Screen Printing Keypad |

| Laser Etched Keypad | |

| Molded Legends Keypad | |

| Protective Cover | Color-filled-in Keypad |

| PU Spraing Coating Keypad (Matte&Bright Surface) | |

| Matte Smooth Coating Keypad | |

| Epoxy Coating Keypad | |

| Plastic + Rubber Keypad (Plastic Key Cap & Cover) | |

| Metal + Rubber Keypad (Metal Key Cover) |

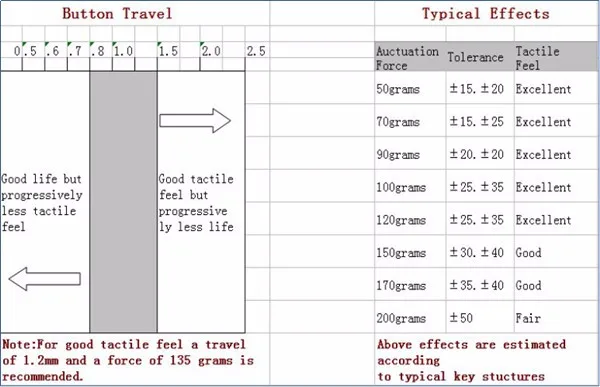

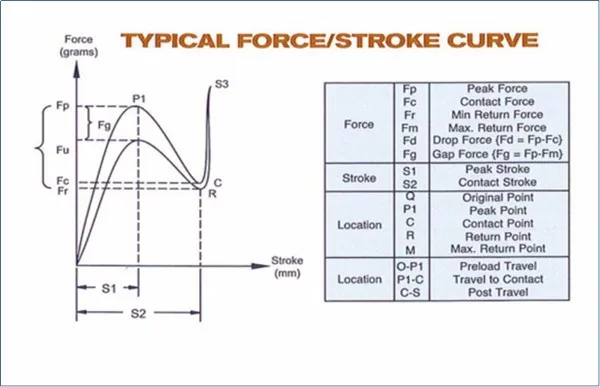

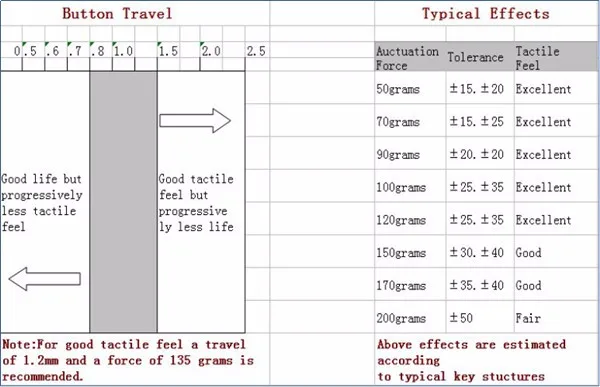

Travel /Stroke Sketch

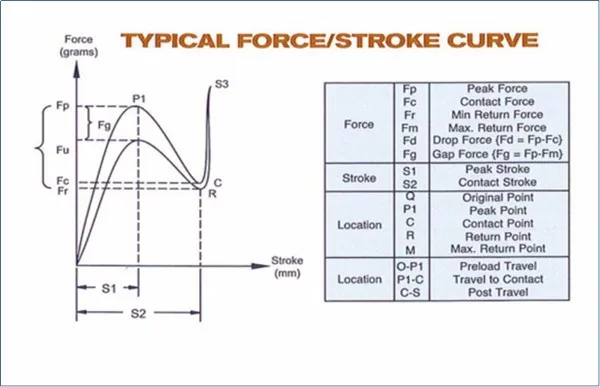

Typical Force/Stroke Curve

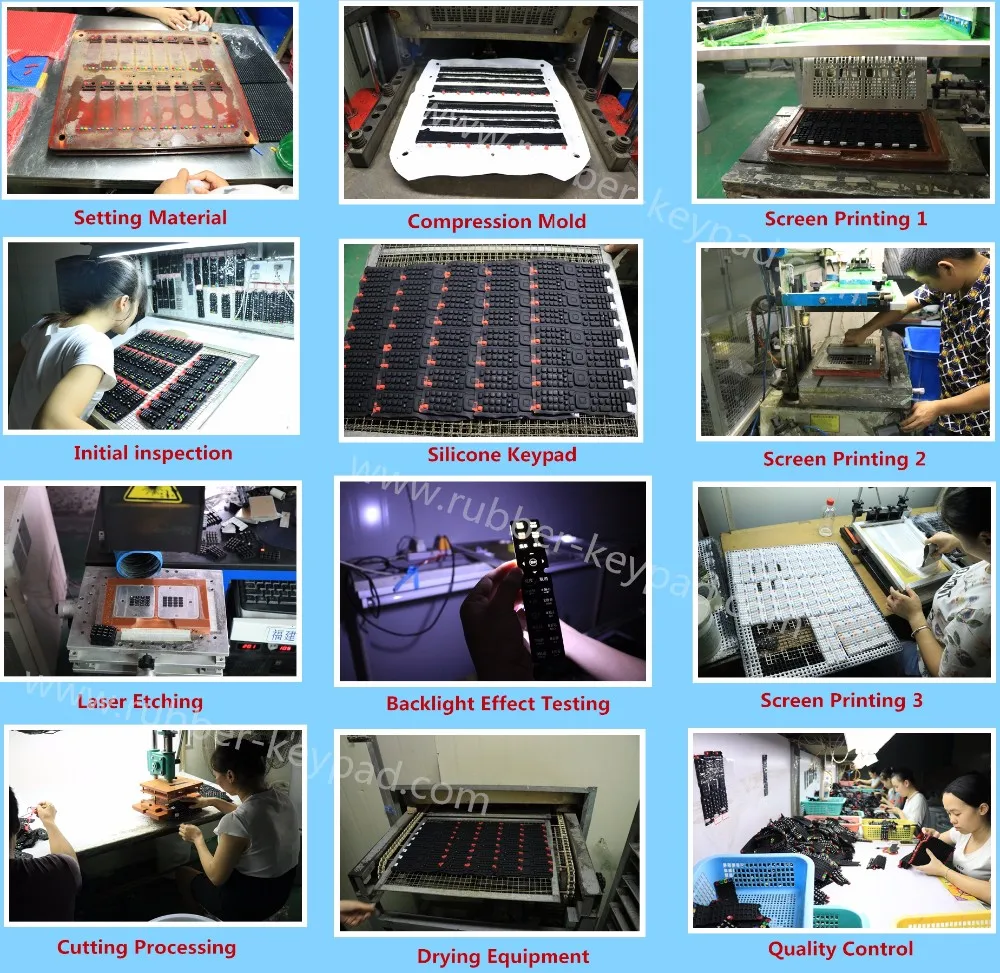

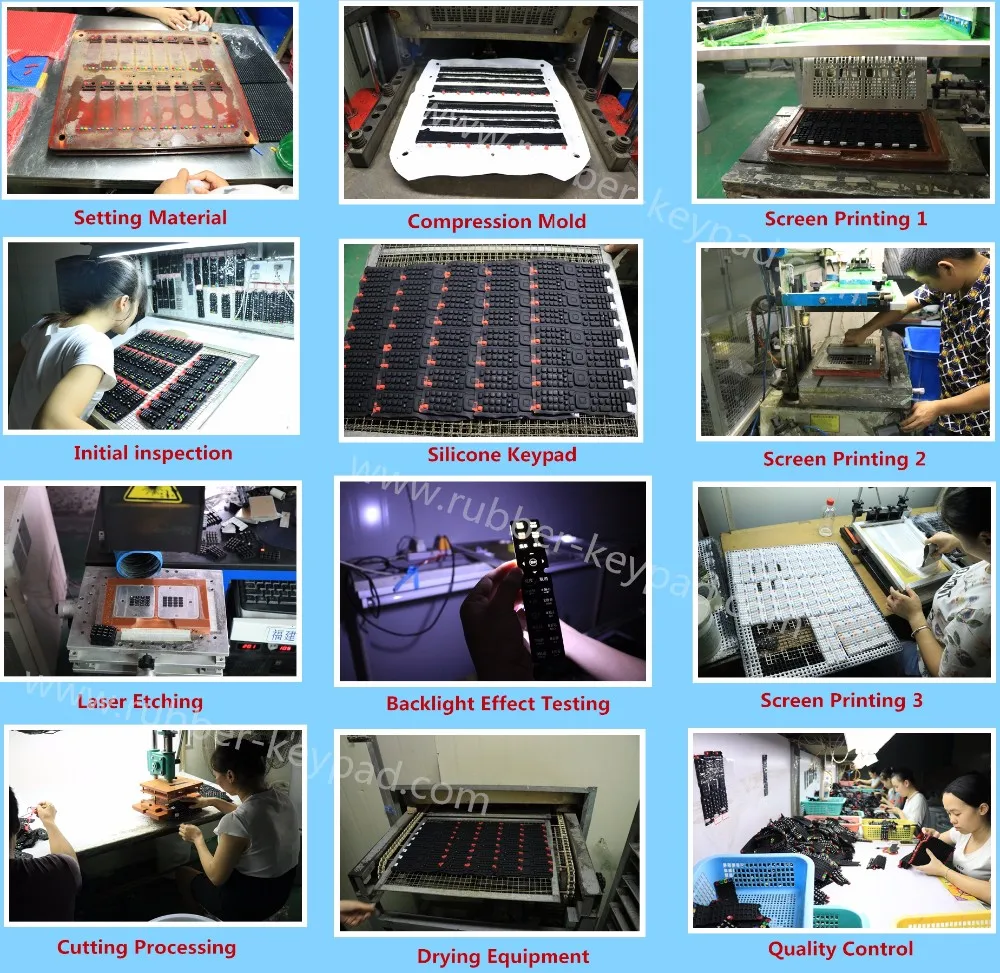

Xiamen Better Silicone Import and Export Co., Ltd is specialized in designing and manufacturing all kinds and configurations of Silicone Rubber Products for a wide range of applications. Our silicone rubber keypad solutions combine excellent conductivity, reliability and long life span, which can meet all the environment's requirements and fit your individual needs.

Characters or symbols on silicone keypad’s surface

We also have single button ,3 button (key) and 5 button (key) button pad.

Make good use of silicone materials characteristics:

Translucent; Or Translucent Silicone + Color Toner

Produce dual or multiple buttons( keys) in one keypads by key-setting tooling.

when molded keypad production

Key top is coated (drop) by epoxy which have abrasion PU Coating is Polyurethane Coating, which is a kind of surface process

resistance function and can resist chemical or oil. for protecting silicone keypad’s character, symbols, or color spraying coating etc

Also improve keypad ornate-crystal beauty. Coated

color ( inner color) is the same to surface legend color.

Take full advantage of the benefits of plastic key cap with the Need laser cutting process to making desired character or symbols.

elastomeric and sealing feature of silicone rubber keypads First coated color ( inner color) is the same to the desired character or symbols color.

by glue or under-cut designs

Common products in our daily life, TV sets, air-conditions etc

home appliance

Protect electronic product’s switch and improve sense of touch.

Made of stainless steel, a part of switch devices. Silicone Keypad with metal pill is known as silicone keypad over molded

Lower resistance and better conductivity. with copper pill, gold pill and so on.

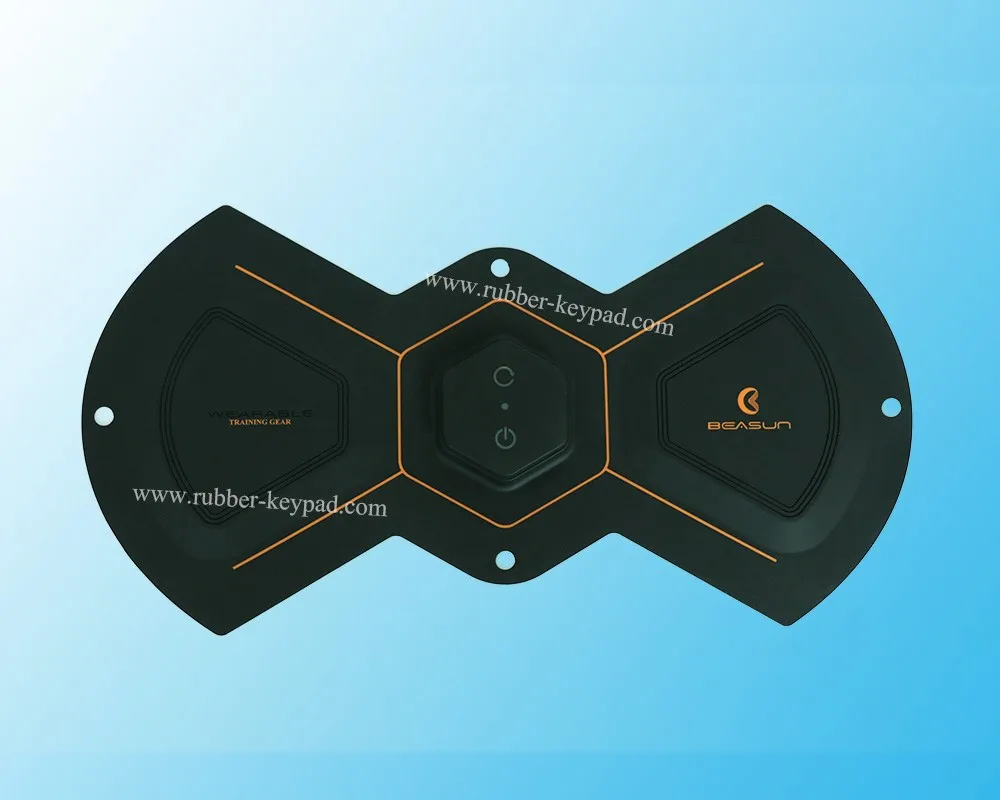

A process for choosing conductivity ink instead of black Buttons + Silicone pad overmolded keypad is in aim to

carbon pills as non-conductive substrate’s conductive improve keypad touch feelings, also have aesthetic feeling

point or conductive circuit. conpared with Key-setting keypad.

Keypad Contact Types

| Silicone Rubber Keypad Contacts | ||||

| | Carbon Pill | Conductive Ink Printing | Metal Domes | Metal Conductive Pill |

| Life Time | About 10 Millions | About 10 Millions | About 10 Millions | Above 10 Millions |

| Resistance | 10-100 Ohms | 50-350 Ohms | 1-100 Ohms | 1-100 Ohms |

| Diameter | 1.5-8mm | Available | Available | Available |

| Thickness | 0.2-0.6mm | 10-20 Microns | 0.05mm-0.1mm | 0.05mm-2mm |

| Advantage | Lower Resistance Stable Life Time | Any Shape is Available | Lower Resistance | Lower Resistance |

| DisAdvantage | Shape Limted | Resistance Limited | Bad Tactile Feel eithout Dust-free Functions | Low Production Efficiency, High Unit Price |

Keypad Legend Types and Surface Protection

| Legends | Screen Printing Keypad |

| Laser Etched Keypad | |

| Molded Legends Keypad | |

| Protective Cover | Color-filled-in Keypad |

| PU Spraing Coating Keypad (Matte&Bright Surface) | |

| Matte Smooth Coating Keypad | |

| Epoxy Coating Keypad | |

| Plastic + Rubber Keypad (Plastic Key Cap & Cover) | |

| Metal + Rubber Keypad (Metal Key Cover) |

Travel /Stroke Sketch

Typical Force/Stroke Curve

Xiamen Better Silicone Import and Export Co., Ltd is specialized in designing and manufacturing all kinds and configurations of Silicone Rubber Products for a wide range of applications. Our silicone rubber keypad solutions combine excellent conductivity, reliability and long life span, which can meet all the environment's requirements and fit your individual needs.

Silicone Rubber Keypad | Self Adhesive Gaskets | Rubber Sealing Gasket | Rubber Bellows | Rubber Button | Silicone Keyboard Cover | Membrane Keyboard | Membrane Switches | Remote Control Keyboard | POS Keyboard | Keypad Legends | Conductive Keypad | Keypad Cover | Keypad Feature | Liquid Silicone Rubber | Screen Printing Keyboard | Laser Keyboard | Conductive Metal Pills | Metal Dome | Conductive Button | Carbon Pills | Conductive Printing | Epoxy Coating | PU Coating | Matte Smooth | Color Coating | Plastic Key Cover | Metal Key Cover | Fluorescent keyboard | Molded Keypad | Backlight Keypad | Translucent Keyboard